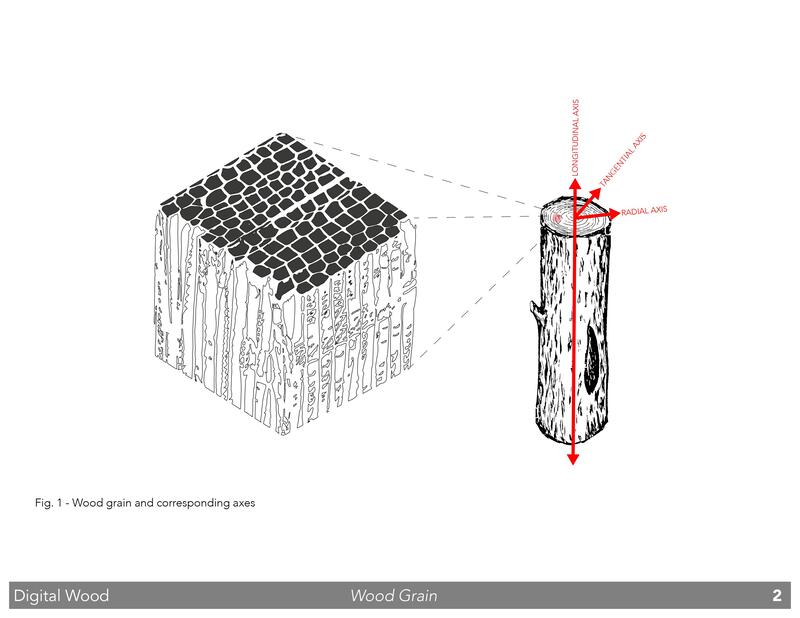

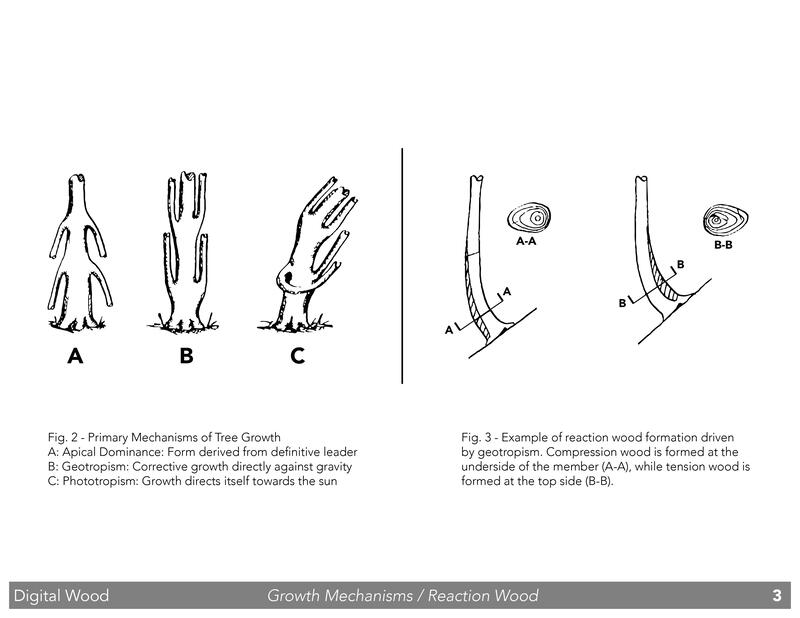

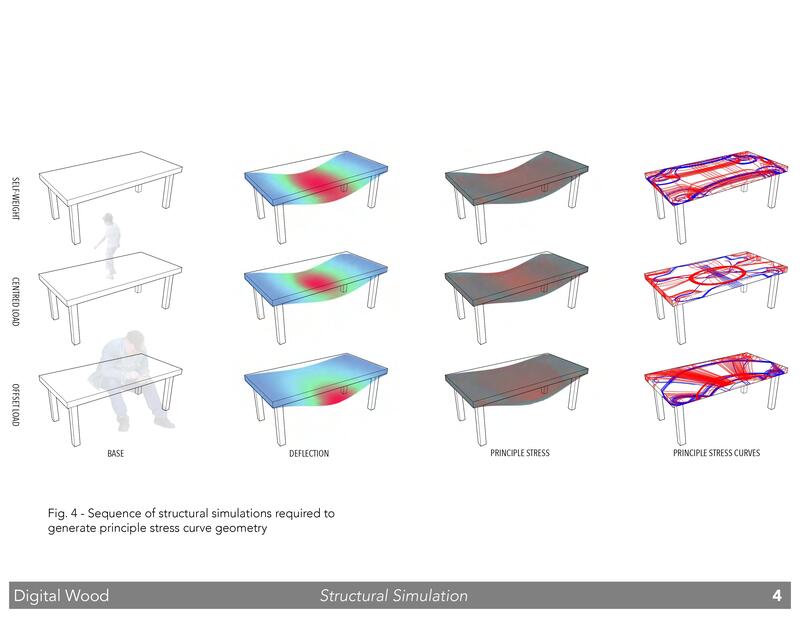

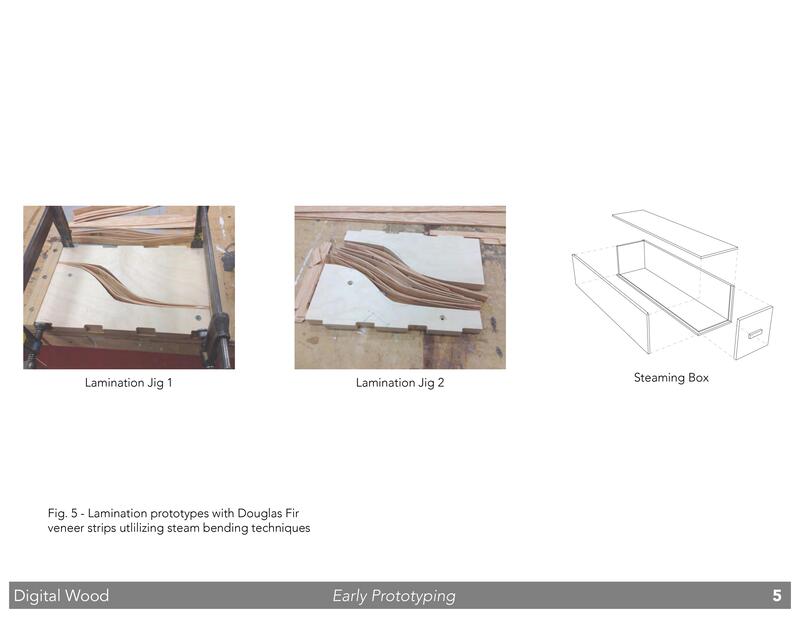

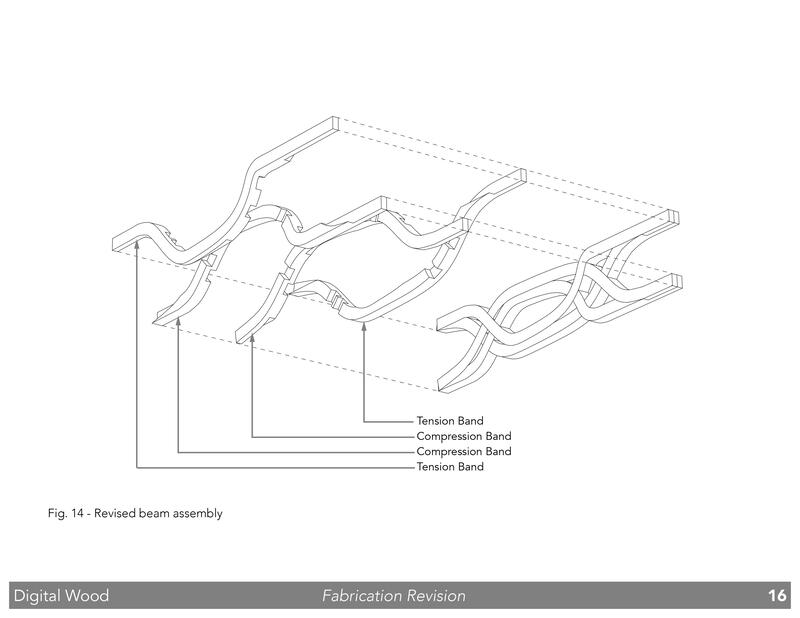

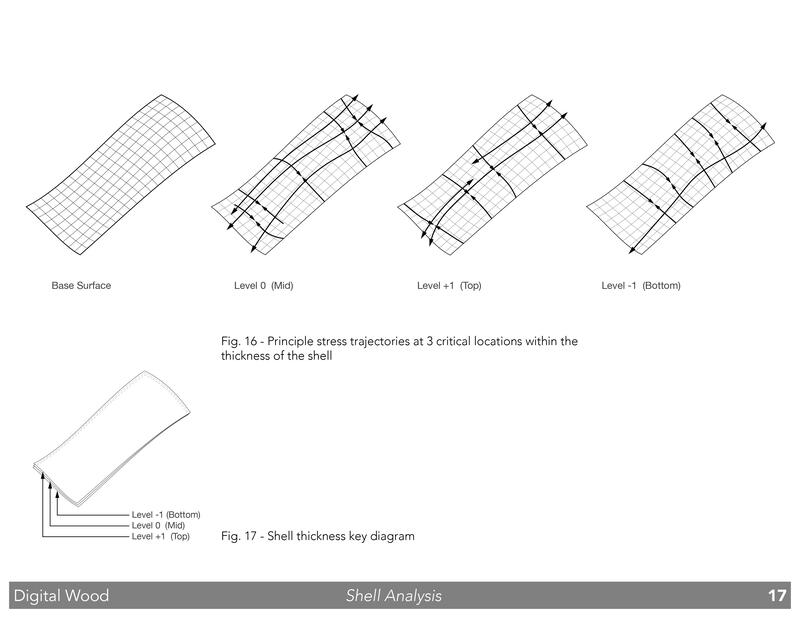

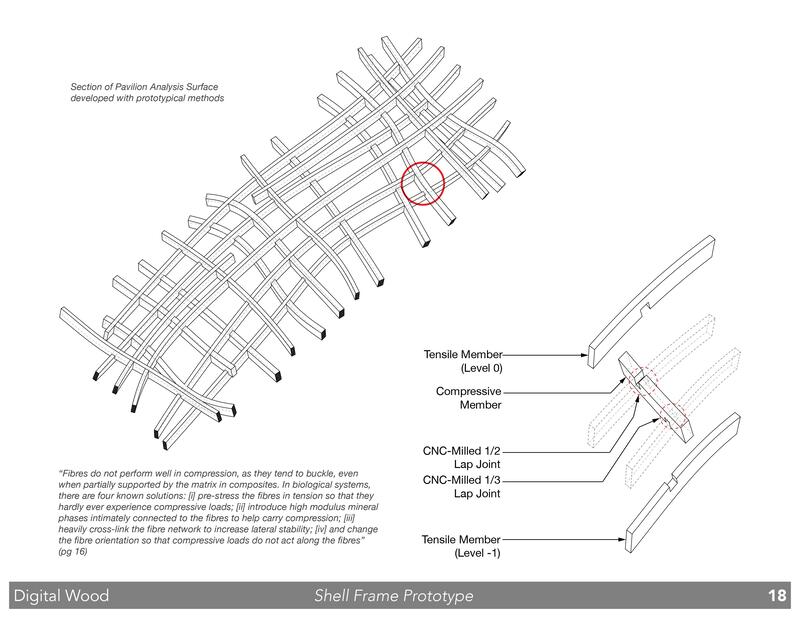

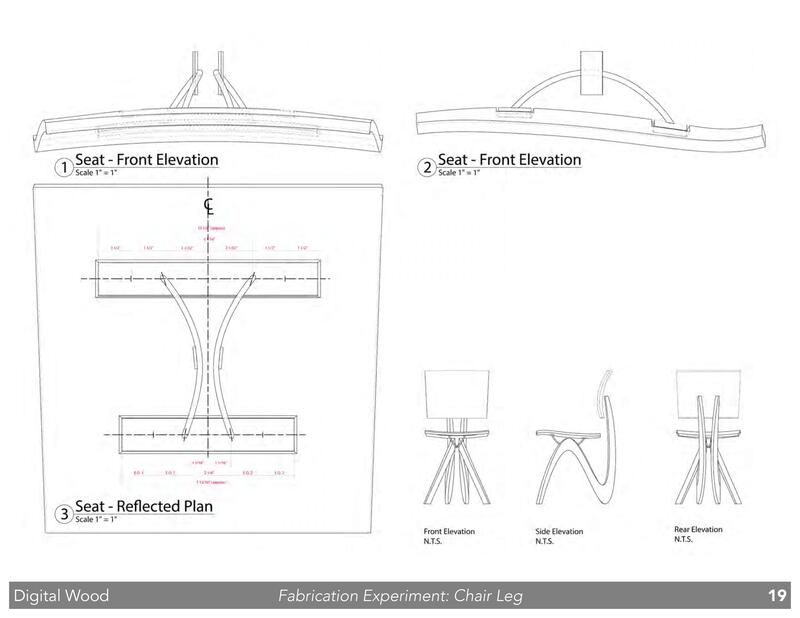

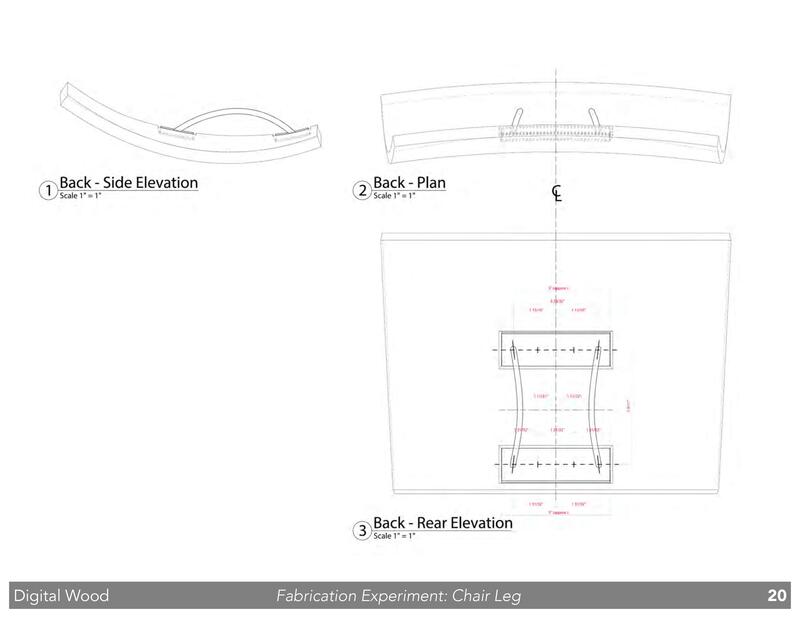

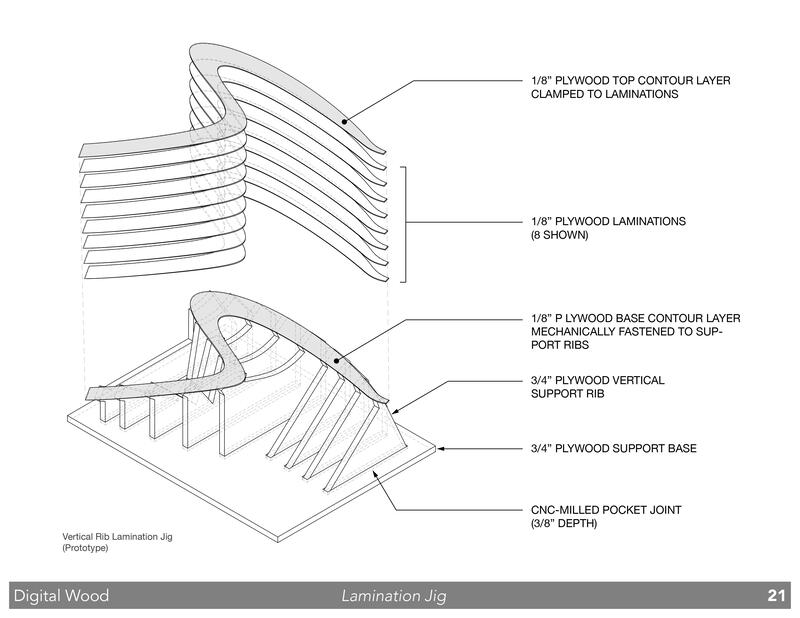

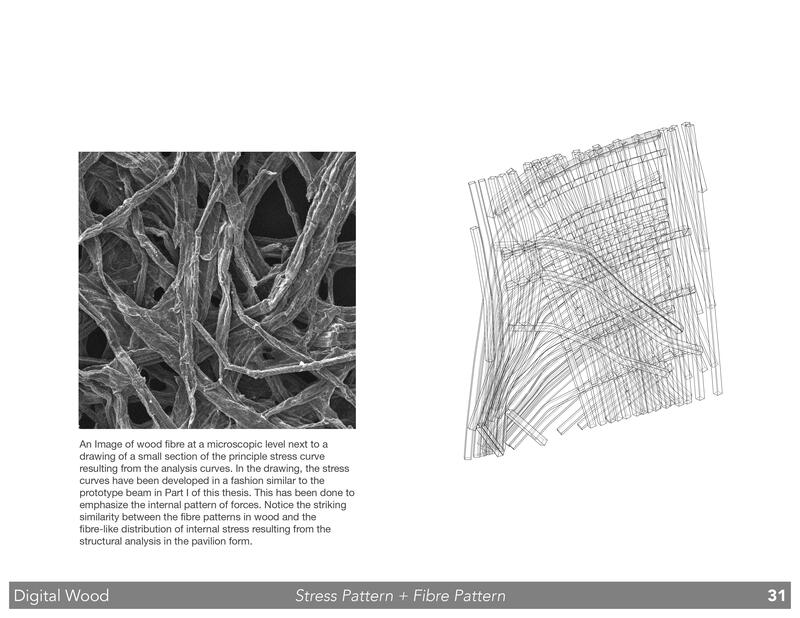

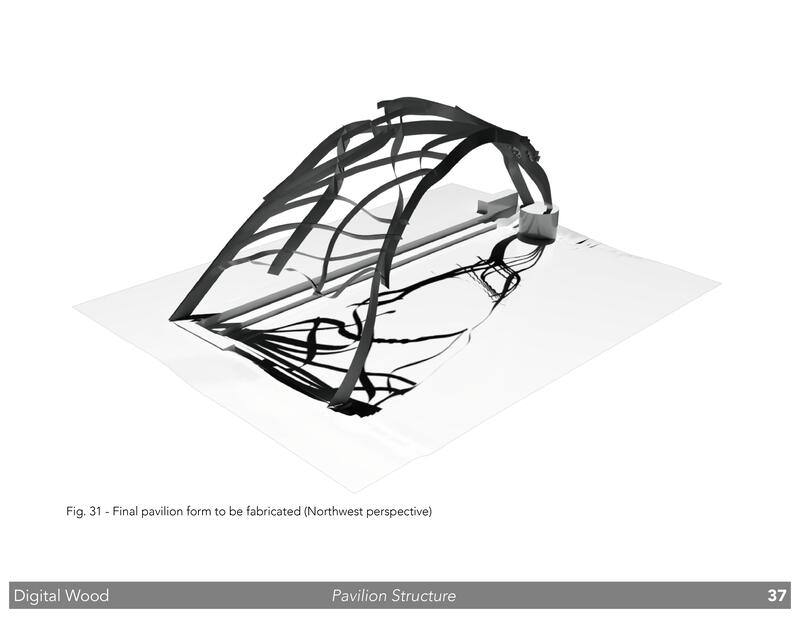

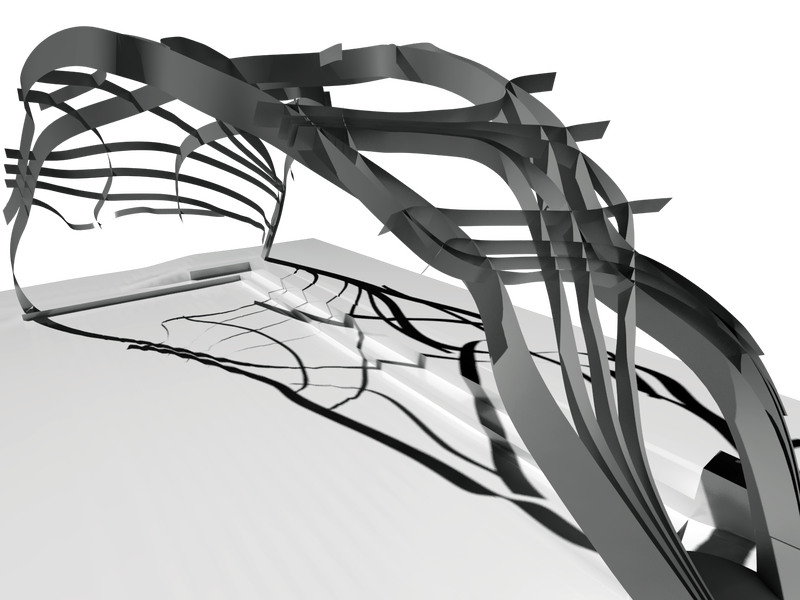

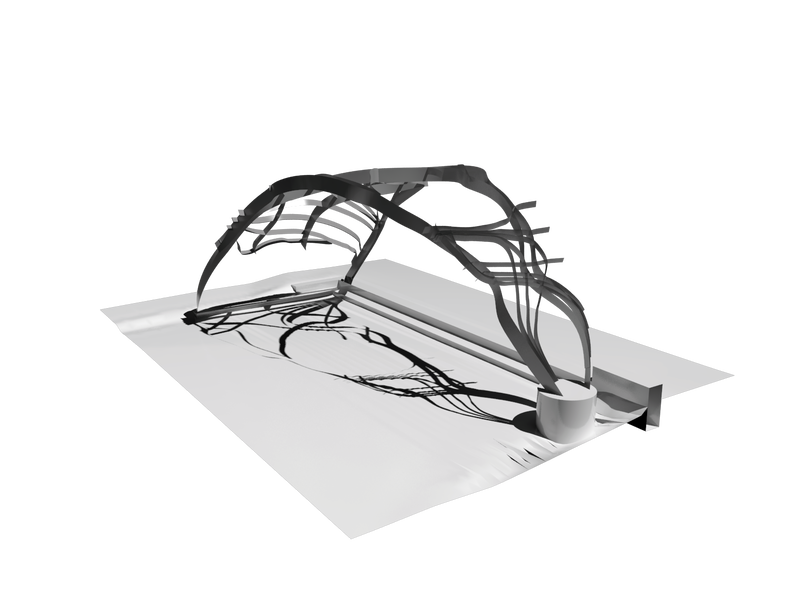

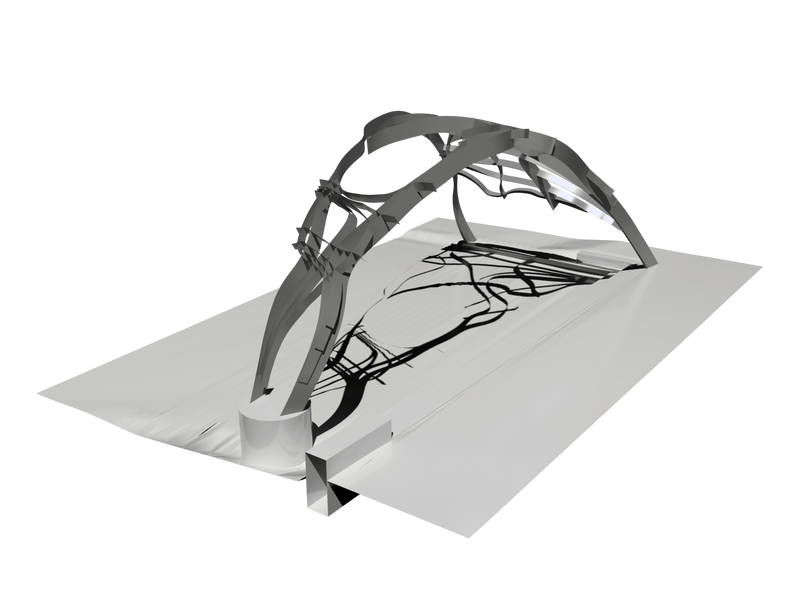

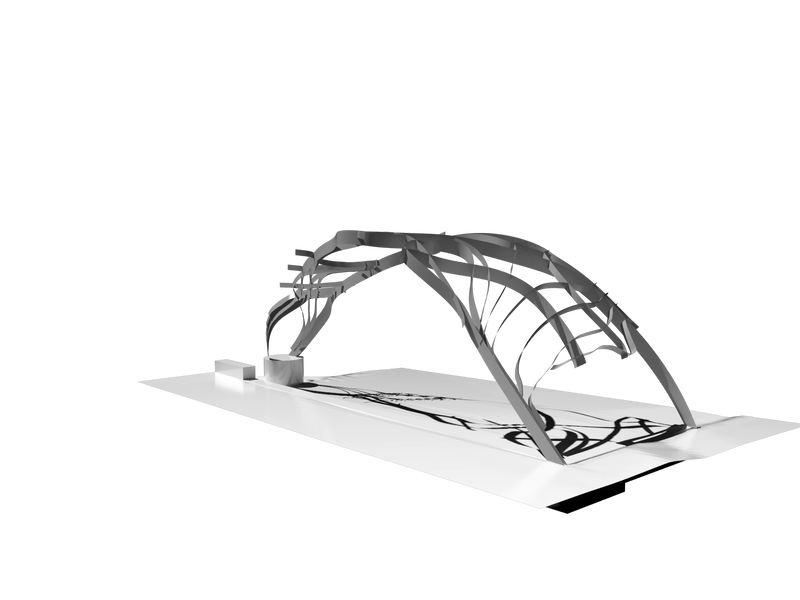

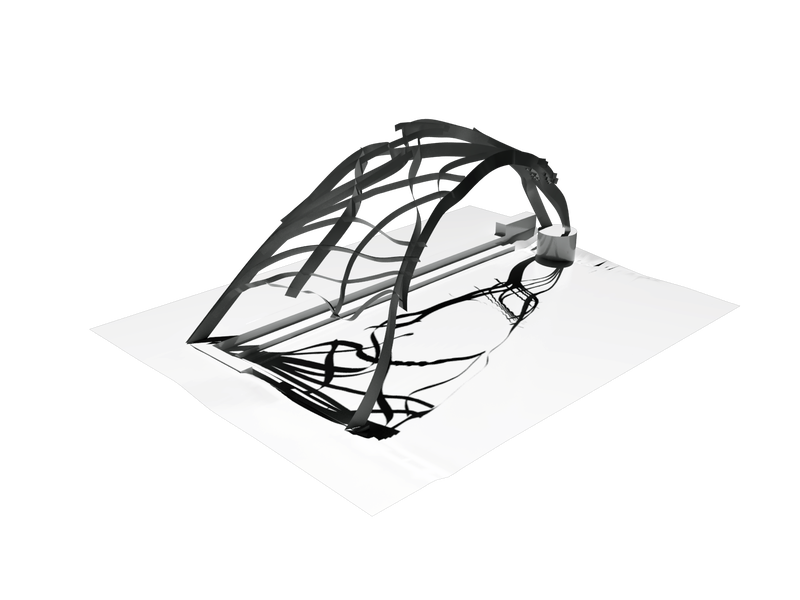

Digital Wood seeks to develop lighter, more delicate, and more efficient structural framing members by computationally realigning wood grain to the corresponding principle stress lines acting within the member while it’s under load. This will be achieved by utilizing computational analysis and design software in conjunction with digital milling tools to produce molds, jigs and formwork required for fabrication. Once fabricated, the resulting framing member will retain the performance properties of the original, but in a fraction of the material and thus a fraction of the weight. This materials research thesis will utilize the intrinsic mechanical properties of wood fibre to produce a superior structural framing system. Digital tools of design and fabrication are capable of not only uncovering these properties, but assisting in precision milling required for grain realignment to be viable option in the construction industry. Through this research, I intend to develop a wood-specific structural design methodology that harnesses the strength properties of wood’s anisotropic nature. The structural system developed from this working methodology will carry loads and distribute forces in a manner that closely resembles that which a living tree would also carry loads and distribute forces. Ultimately Digital Wood will explore alternative methods of designing and fabricating structural wood components that utilize the properties of wood grain in the most appropriate manner possible and make a meaningful contribution to both the fields of architecture and structural engineering that affirms the versatility and dependability of wood building products.